A few days ago, another large-scale equipment in Weihua Crane Intelligent Industrial Park was officially put into use. A 16m×8m×6m heat treatment annealing furnace for heavy structural parts successfully realized the overall annealing of a 320t metallurgical trolley.

As the core process and processing technology of large metallurgical cranes, this large annealing furnace can meet the annealing treatment of various structural parts of large metallurgical cranes of 500t and above.

1. Precise temperature control

The furnace temperature control accuracy is high, the temperature control accuracy is ±3℃, and the furnace temperature uniformity in the same zone is ±10℃. It adopts PLC control mode to automatically realize multiple heating processes.

2. Intelligent control

Three-dimensional heat storage, zoned furnace temperature control, nozzle size and arrangement can be set according to actual needs, so that the workpiece is evenly heated in the furnace.

Before annealing

Annealing

Furnace temperature control system

After annealing

According to the product structure, Weihua has formulated a special annealing process, which can improve or eliminate various structural defects and residual stresses in the welding process, improve the comprehensive mechanical properties of the workpiece, and prevent the workpiece from fatigue deformation damage and weld joint cracking, and eliminate Potential safety hazards to ensure the dimensional stability of each organization.

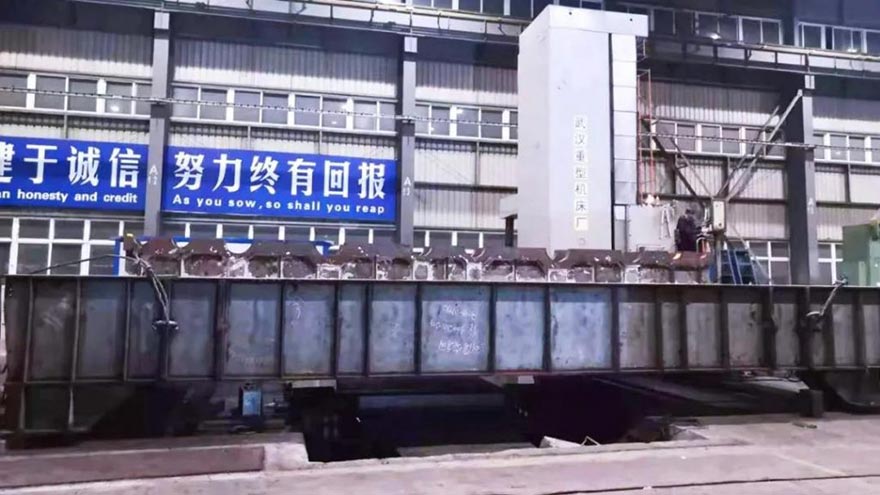

Overall processing of large metallurgical crane reducer

Full-size processing capacity coverage

Large-scale CNC floor boring and milling machines such as 260mm and 200mm spindles, CNC gantry boring and milling machines and other equipment, as well as corresponding processing tools and cutting tools, have formed a full-scale, high-precision processing capacity coverage for large metallurgical crane structural parts of 300t-500t and above.

Combined process combined processing

The processing mode is transformed from discrete single-piece independent processing to sub-component combined process combined processing, and the whole process process quality control mode is constructed.

Overall machining accuracy

It can realize the combined processing of large components and full-size large area, multi-directional boring, milling and drilling. The linear positioning accuracy is 0.02mm, the axis parallel accuracy of each hole system is 0.015mm, and the flatness of the joint surface is good.

Key performance

For a long time, Weihua Crane has continued to supply a variety of intelligence to large steel and metallurgical enterprise groups such as Baowu Iron and Steel, Shougang Group, Anshan Iron and Steel Group, Anyang Iron and Steel, Jingye Iron and Steel, Jingtang Iron and Steel, Anfeng Iron and Steel, Lingyuan Iron and Steel, Phoenix Iron and Steel, etc. Chemical metallurgical lifting products have won unanimous praise in the industry.

Angang Zhoukou Iron and Steel 300t Metallurgical Crane Project

Qingshan Stainless Steel 320t Metallurgical Crane Project

Jinxi Iron and Steel 320t Metallurgical Crane Project

Pingshan Jingye Steel 320t Metallurgical Crane Project

Purui large-scale one-word metallurgical reducer project

If a worker wants to do his job well, he must first sharpen his tools. In order to cope with rapidly increasing orders and capacity demands, the Weihua Crane Intelligent Industrial Park was fully launched and advanced at full speed. A number of intelligent production lines have been put into use one after another. Weihua Group has mature production technology and complete equipment configuration of large metallurgical cranes, and controls the entire process.